Department of Energy SETO director Dr. Jones-Albertus delivered the keynote address at pv magazine’s recent Roundtables US 2023, addressing the energy transition and the growth of domestic solar manufacturing.

Achieving the White House’s goal of 80% clean energy supply by 2030 is possible but is not without some challenges.

Supporting the buildout of solar in the U.S. is the Solar Energy Technologies Office (SETO), which focuses on advancing technology and accelerating solar deployments by driving innovation in technologies, solar panels supply chain to inverters to soft costs. While working to scale up solar, SETO is also focused on ensuring that solar can support the reliability, resilience and the security of the grid.

Dr. Becca Jones-Albertus, Director of SETO, was the keynote speaker at the pv magazine Roundtables US 2023, where she shared her thoughts on how SETO is focused on how solar can factor into the buildout of renewable energy in the U.S. along with how solar can support job growth, equitable opportunities to benefit from an energy transition, growth of domestic solar manufacturing, as well as its role in a circular economy.

Dr. Jones-Albertus noted the great progress that the U.S. has made in solar deployment, now being the second largest market behind China. To reach the current goal of decarbonizing the power grid by 2035, however, will take another 1000 GW of solar deployment which has some challenges to face.

Geographical diversity

The first of these challenges is geographical diversity. Jones-Albertus said that SETO focuses on a secure supply chain that is geographically diverse and is made up of “financially healthy companies that can scale their production to meet increasing demand”. While the supply chain has shifted to more manufacturing in Southeast Asia, the global supply chain is still heavily concentrated in China.

The chart above shows the different silicon supply chain segments that each have more than 80% of production in China. Even though the U.S. has been able to procure cells and modules from Southeast Asian countries, ingots, wafers and other supplies such as frames, glass and even manufacturing equipment is still coming from China.

Building a U.S. supply chain

She noted that the DOE is very focused on how they can help support and build a U.S. supply chain as one of the key strategies for building resilience.

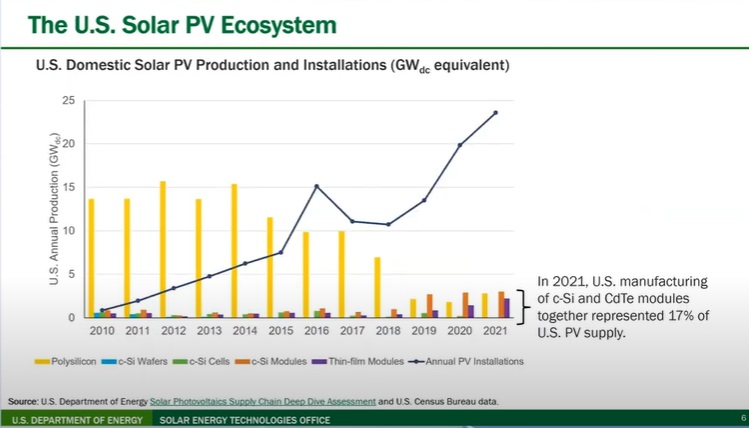

Looking at the chart above, the rising purple line shows the rapidly growing solar installation in the U.S., with the bar chart below showing manufacturing capacities. Ten years ago we had significant polysilicon production until the AD/CVD tariffs caused that production to fall substantially.

This is “all poised to change,” she said, due to the passage of the Inflation Reduction Act, “the most significant piece of legislation we’ve had in this country when it comes to domestic solar manufacturing”.

As a result of the manufacturing production tax credits and the domestic content adder, we’re seeing tremendous growth in U.S. solar manufacturing. She noted that the reason the numbers were so low prior to 2021 was because we have higher costs in this country for labor, electricity, land acquisition, permitting and environmental burdens, etc. “All for good reason,” she said, but the tax credits offered by the IRA offer an opportunity to use those costs and become more competitive.

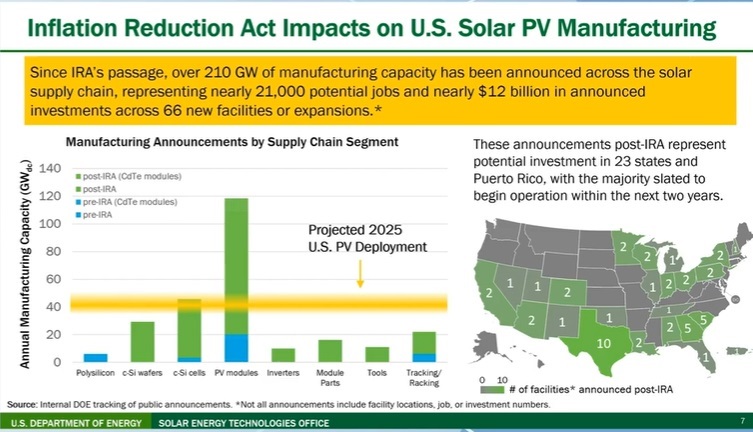

As shown in the chart above there has been an incredible number of manufacturing announcements across the supply chain from silicon wafers to cells to modules to trackers, and to a lesser extent to polysilicon, inverters, and tools.

Cumulatively across the supply chain, SETO estimates that it’s over 210 GW of capacity. It’s over 20,000 jobs, nearly $12 billion in investments. This includes an announced 66 new facilities or expansions across 23 states in the US and Puerto Rico. She acknowledged that not all of these will come to fruition, but there may be additional announcements to come.

As the U.S. solar supply chain scales, SETO provides support for the very beginning of ideas all the way through to those who have developed their technology and are looking to pilot scale manufacturing. The office helps prepare new technologies to be ready to apply for loans from the DOE loan programs office to help scale into full production.