Quanex has released a new moisture protectant for solar panels that solar panel manufacturers can apply during the final manufacturing process. SolarGain Edge Sealant LP03 is a polyisobutylene butyl rubber adhesive with integrated desiccant.

Quanex said SolarGain Edge Sealant can be especially useful as emerging technological trends (like perovskite and heterojunction designs) have exposed a need for higher levels of moisture protection.

Quanex said SolarGain Edge Sealant can be especially useful as emerging technological trends (like perovskite and heterojunction designs) have exposed a need for higher levels of moisture protection.

Solar panel manufacturers often turn to ethylene vinyl acetate (EVA) encapsulants, but Quanex said in a press release that EVA has the potential to generate acid that can decrease solar output due to the corrosiveness of the acid when exposed to moisture over time. Alternative encapsulants like thermoplastic polyolefin (TPO) and polyvinyl butyral (PVB) have also demonstrated higher potential to resist moisture ingress vs. EVA but are considerably more expensive and difficult to handle during the assembly process.

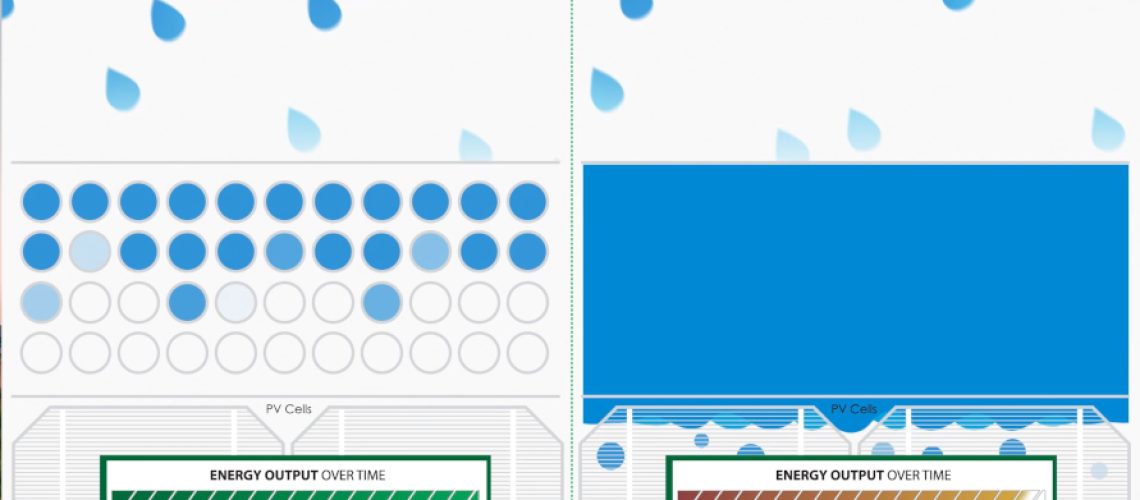

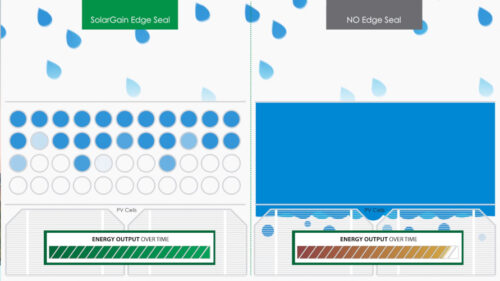

By helping to prevent moisture ingress in solar modules, SolarGain Edge Sealant helps better protect cells, connections and conductive coatings to maximize performance and longevity. Quanex suggests an additional 10 to 15 years of useful life can be added to a solar panel with use of its sealant.

SolarGain Edge Sealant is backed by Quanex’s 50 years of experience in insulating glass (IG) sealant and spacer manufacturing designed to slow moisture entry between glass panes. These IG solutions must demonstrate many of the same attributes required in solar module sealants, including UV resistance, flexibility through a wide variety of temperatures and the ability to delay the migration of moisture.

News item from Quanex