Kinematics, a company manufacturing motion control systems, has developed an all-in-one controller and actuator solution that can help solar structure manufacturers integrate PV tracking capabilities to their portfolios. The company is debuting this new product at RE+ 2023 in Las Vegas at booth 538.

Kinematics ONE

“Competitive pressures in the rapidly growing utility-scale solar market require providers to deliver competitive costs and ‘bankable’ performance. Add the financial incentives for using trackers in the Inflation Reduction Act, and you have an enormous opportunity for Ground-Fixed-Tilt suppliers,” said John Payne, CEO, Kinematics, “Kinematics ONE gives established suppliers a competitive edge and enables smaller tracker suppliers to serve this growing market effectively.”

Kinematics ONE is being sold to C&I and utility-scale ground-fixed-tilt structure providers seeking to add tracking capability to their product portfolio, and existing tracker companies seeking an integrated motion control solution. It can also re-power or upgrade the control systems within existing solar plants.

“The IRA creates a lot of incentives for tracker technologies, and this can open the incentives to companies who don’t participate in trackers,” said Jenn Cangelosi, VP of global sales and business development at Kinematics, in a media briefing with Solar Power World.

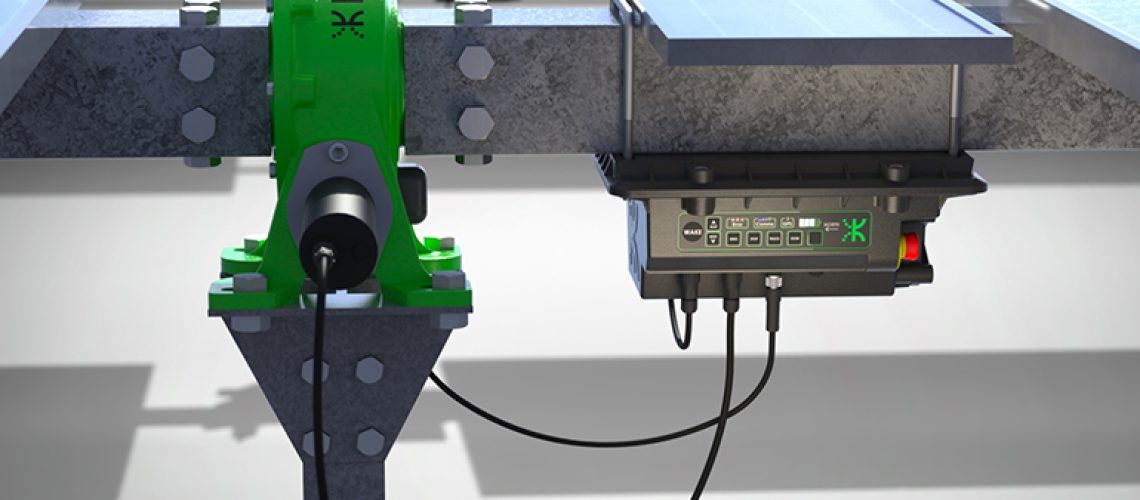

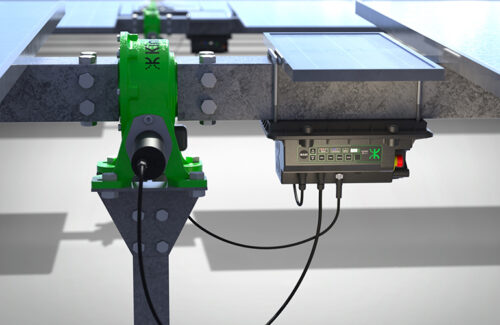

Kinematics ONE is a complete actuation sub-system combining Kinematics drives, motors and motion controls into a single commissioned package. Solar structure manufacturers specify the required structural design and loads so Kinematics can supply a turnkey system. This way, customers won’t need to engineer and qualify their own actuation and controls design.

“Every tracker customer we’re working with is going to be unique,” said Robin Wessel, VP of product management and corporate development for Kinematics. “Our system has design flexibility and customization for each customer. They’re all going to have different designs, loads, drive sizes, motors, as well as labeling and packaging deployment requirements. We are ready to work and tailor this product to meet the specific needs of our tracker OEMs, whether that’s an established manufacturer or a ground-fixed-tilt manufacturer new to tracking.”

SOL Components is one of the first manufacturers in the solar racking space to pilot Kinematics ONE on its structures in the field, and Kinematics is testing the packaged actuator and motion controls at its facility in Phoenix, Arizona.

“Kinematics ONE provides an essential capability to help us meet the demanding and evolving utility scale tracker system needs of the leading EPC firms on the largest solar projects in the country,” said Mike Fraenkel, CEO of SOL Components. “This fully integrated system will speed our development and certification process and ensure we deliver the best-in-industry tracker solutions.”

Kinematics ONE uses the Wi-SUN FAN (Field Area Network), a remote network system that’s had 100 million nodes already deployed for utilities, oil and gas, street lights, electrical meters and other indistrual applications. This is the first time Wi-SUN has been adapted for use in tracker controls

Kinematics ONE was designed to meet UL3703 standards and includes documentation needed for end-customers to certify their trackers. Each actuator is self powered with a battery to reduce the trenching required for running strings to the tracker.

“What we’ve heard from our customers is reliability and cost of ownership are top orders,” Wessel said. “You can introduce ‘whiz-bang’ features and cool technological, extra fancy mapping and improve production by 2% with this, that or the other, but don’t sacrifice cost-effectiveness.”

Kinematics ONE integration planning will start immediately, with volume production beginning in the second half of 2024. For more information, visit this website.

News item from Kinematics