The residential microinverter manufacturer released a 208V three phase inverter for the small commercial market. The advancing hardware comes with a specialized support team, expedited one-day financing options, and tailored design tools – optimized for efficiently handling systems up to 200kW.

Microinverter manufacturer Enphase has officially launched its dedicated 208V three-phase offering. The company says a focused support team, evolving hardware, financial solutions, and design tools are being made available for small business solar projects. The manufacturer says system sized blocks of 200 kW will most efficiently maximize their hardware on a cost-per-watt basis.

Previously, 120V single-phase residential Enphase inverters could be configured into 208V three-phase commercial systems. However, this required meticulous system design and additional “Q Cables”. The new 208V system offers more flexibility in string design and simplifies installation with a new four-wire 208V Q Cable.

Eric Bergman, Commercial and Industrial Sales Director at Enphase, touted the advantages of the new system to pv magazine USA. Bergman explained that installers used to have to “physically land the output of the micros evenly across the three phases of the site.”

Installations also used to require a network protection relay, necessitating an external enclosure. The new IQ8 C&I microinverter comes with the 4-wire QD Cable, which integrates phase balancing, V/F ride-through, and loss of phase detection – functions previously managed externally by the Network Protection Relay.

Enphase anticipates that all hardware and associated equipment will be classified as domestic content, potentially qualifying for the 10% Inflation Reduction Act tax credit adder. However, the definitive guidance from the Internal Revenue Service is still pending.

U.S. production of the commercial inverter is set to begin in the first quarter of 2024. Enphase is initially focusing on the core functionalities of the 208V equipment, with plans to introduce additional features like grid-tied load support, energy storage integration, and 480V three-phase support in the future.

Bergman highlighted another benefit: a large, skilled workforce is already trained to sell and install these systems:

Right now, the nation is seeing a bit of a slowdown in residential solar sales. At the same time, commercial solar contractors are having a challenging time finding installation crews. The 208V gear gives both groups multiple opportunities. Residential installers who’ve been installing Enphase their whole careers can be tapped by commercial groups to help them deploy these systems, or sell to small businesses on their own.

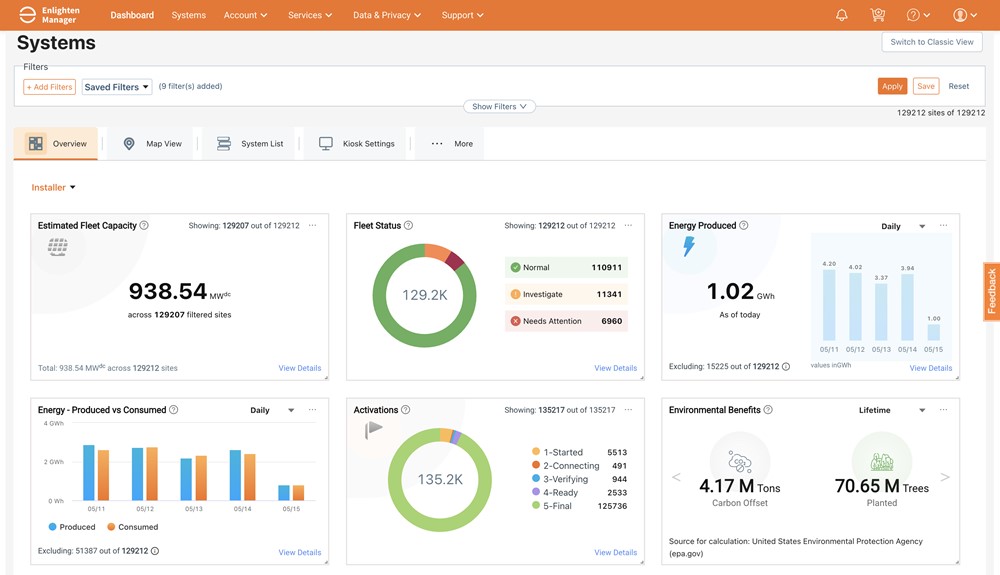

Enphase has also developed new software tools. The first, Fleet View, allows commercial installers to monitor and manage all Enphase installations at a module level. There is also a kiosk feature, which provides a public-facing website for remote monitoring of solar power systems. Additionally, Enphase’s SolarGraf, solar design software acquired in 2021, has been optimized for their products.

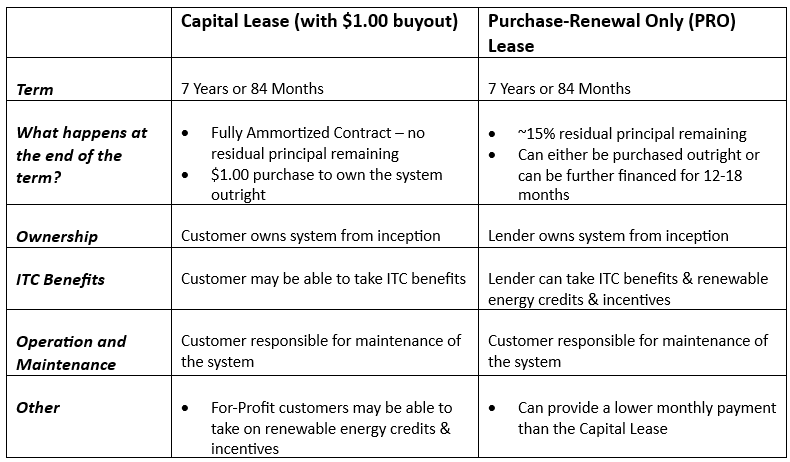

Another innovative software feature from Enphase is a new financing option. This option becomes available once a design is completed in SolarGraf. Users can then apply for a lease directly through Bank of Montreal, integrated with the SolarGraf platform. The bank offers two seven-year lease products: one that enables the bank to claim the tax credits, while the other option leaves the tax credits with the business owner. For projects valued at less than $150,000 the application process is swift, with responses typically provided within 24 hours. For larger projects, the approval process may take up to two or three days.

Bergman views the bank’s involvement as a testament to Enphase’s reputation. He believes the bank sees Enphase as an “investment grade inverter, if you will.”

Enphase has already deployed fifteen 208V sites in the U.S., Mexico, and Canada during their beta program. Bergman, an expert with extensive experience in commercial inverters, reported impressive efficiency in the installations, said “If we look at our entire beta testing installation portfolio for our C&I products, each site took on average approximately 30 minutes to commission and 100% of the sites required only one truck roll to complete.”