CEA has suggested that solar wafer pricing will fall 23% by the end of 2023, while Bloomberg NEF sees 500 GW of manufacturing capacity online by the end of next year.

Solar polysilicon has reached its highest pricing since 2011, when the price of polysilicon hovered between $60 to $80/kg for about two years as the industry cooled off, following the $460 per kilogram peak seen in early 2008.

According to a spot market analysis by China Nonferrous Metals Industry Association, last week’s price touched $45.47/kg, before settling a bit lower. This is an increase of over 600% from the low pricing of under $7/kg, seen in the second quarter of 2020.

Source: Bernreuter Research

If we consider that it takes about 3 grams of raw polysilicon to create each watt of a solar panel, then a 400 watt residential solar panel uses 1.2 kg of polysilicon. The largest panels – 700 watt utility-scale modules – use 2.1 kg. At today’s pricing, that is $51 of polysilicon for the residential panel, at 12.7¢/watt. The 700 watt utility scale panel contains $90 of polysilicon.

Keep in mind that these spot market prices are likely much higher than the prices being paid in long term contracts. The cost of polysilicon inputs hasn’t risen nearly to the same heights, so companies that produce their own polysilicon are actually paying much less for their input costs.

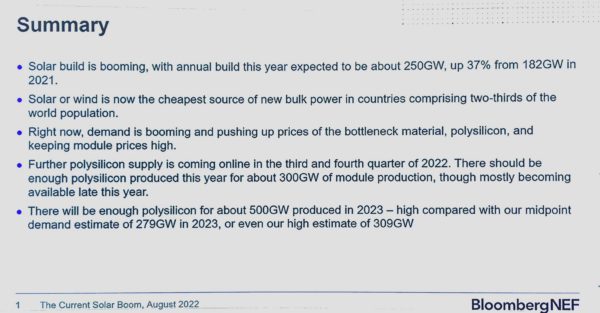

Multiple parties have suggested that the industry should see significant volumes of polysilicon manufacturing come online as the year ends, which would lead to decreases in pricing starting in 2023.

Clean Energy Associates (CEA), in their PV Price Forecasting Program Q2 2022, says they expect ‘significant expansions among ingot and wafer suppliers are expected to create a competitive market scene when these suppliers can once again source lower-priced Polysilicon.’ The group says that by the end of 2022, the world will have approximately 285 GW of polysilicon manufacturing capacity online.

While the executive preview version of the report doesn’t share future polysilicon pricing, CEA does suggest that the average 2022 wafer pricing of $0.13/W could fall as much as 23% by the end of 2023. This implies that polysilicon pricing could fall by roughly $10 per kg. This will lead to solar modules – priced at $0.27/W FOB China for Q4’22, and $0.26/W FOB China for Q1’23 – to fall to $0.23/W by the end of 2023.

Bloomberg NEF recently suggested that by the end of 2023, there will be enough polysilicon manufacturing facilities to supply 500 GW of solar modules.