Even with the threat of heavy snow (that turned into a light drizzle), solar professionals flocked to the RE+ Northeast event in Boston’s Seaport district, for an expanded convention center floor hosting over 200 booths with thousands of attendees. The RE+ Northeast show, located in New England in February, has grown from its humble beginnings in the Westin hotel to the cavernous Boston Convention & Exhibition Center, with plenty more space for future growth!

Now, onto the floor!

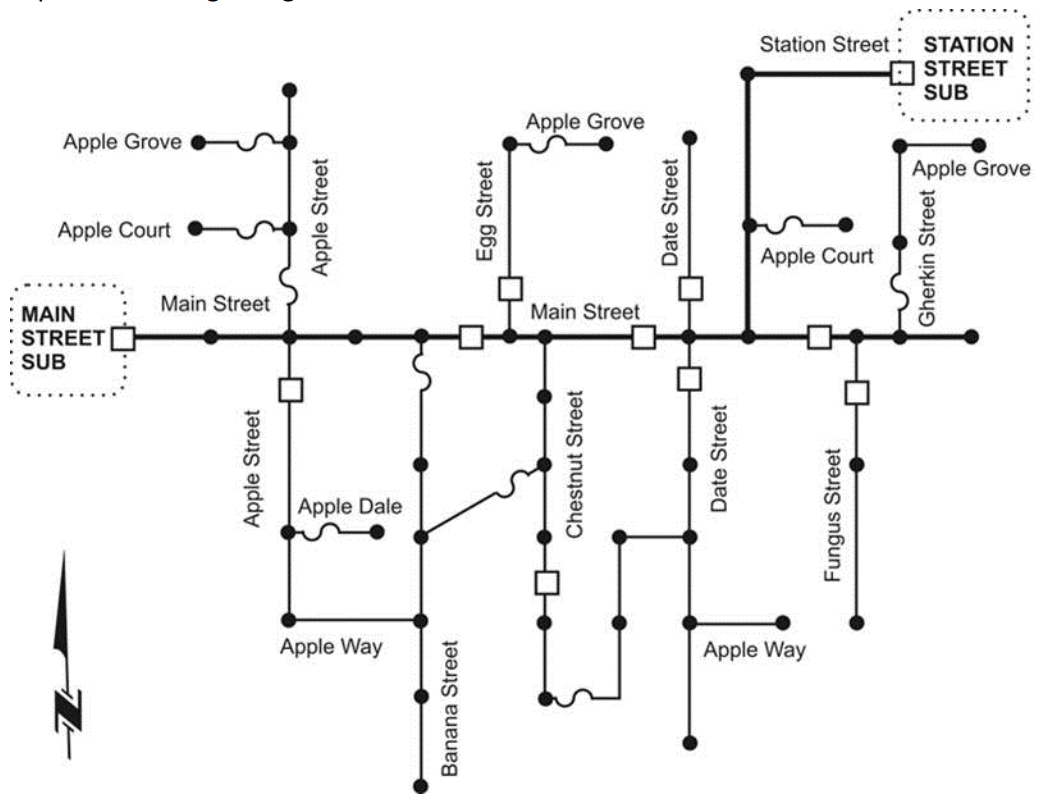

Sun Ballast has reduced its use of aluminum racking components by 95%, opting instead for concrete racking components. This approach simplifies the installation process and utilizes the weight of the concrete racking for ballasting, effectively securing modules to the roof.

As seen in the image above, metal clips secure the modules to the ballast components. pv magazine USA reached out to a tax attorney to determine how the Inflation Reduction Act’s (IRA) domestic content bonus, which requires a 40% average of “Made in America” components across the basket of products, will categorize the ballasts. The question at hand is whether the concrete racking components will be considered part of the 40% basket with some flexibility in sourcing, or if they will be subject to a stricter “Made in America” requirement as standard structural components. This distinction will impact how these components can be used to meet the domestic content requirements of the IRA.

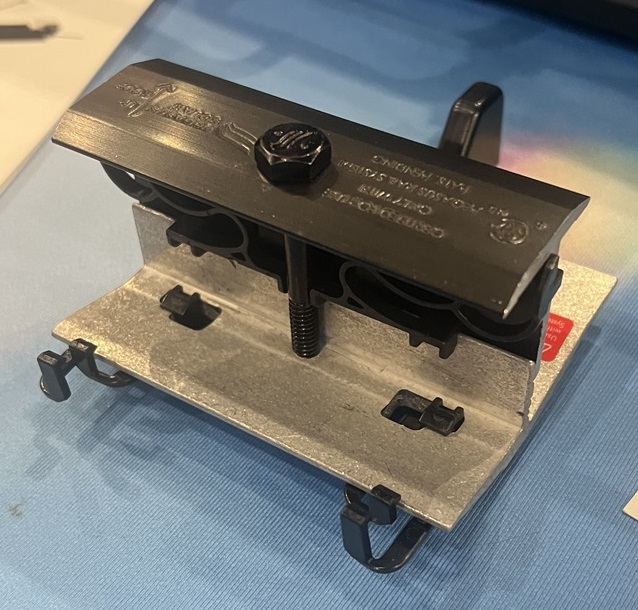

Pegasus showcased two unique products: one that eliminates the need for caulking during attachment and another that reduces the number of racking components needed. The company’s InstaFlash unit integrates a non-hardening, semi-liquid sealant into the flashing, which fills any spaces made by drilling lag bolts into a roof.

The product is designed to squeeze out of the flashing when the integrated lag bolt is tightened, ensuring a secure and watertight seal.

Pegasus’ second product on display, SkipRail, is a mid-clamp product that sits between modules and connects two separate rows together. This design allows installers to skip adding a set of rails and flashing as well as holes in the roof, for the row of modules that connects to a standard two-rail row of modules.

Anker, traditionally known for making small portable batteries and other gadgets, has launched a home battery system. The system features an inverter with up to 6 kWac of standard output, which can be combined with up to six 5 kWh battery packages, totaling a potential 30 kWh.

The Solix X1 battery chemistry is lithium phosphate, which contains no cobalt.

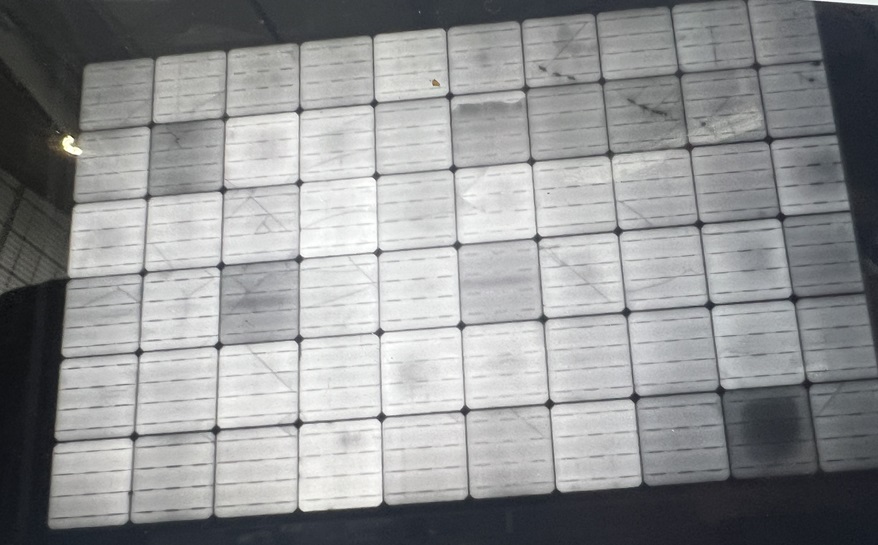

SolarPanelRecycling.com showcased a sampling of the materials it recycles from solar panels during the deconstruction process, including silicon, plastic, copper, and glass. The featured image at the top of this article provides a visual representation of these materials after deconstruction. The company claims it has the capacity to recycle 100 million pounds of material per year, which equates to approximately 2 million solar panels.

All Correct Solar offers EL imaging services, with Beryl Weinshenker, formerly of PVEL, highlighting the company’s ability to provide deliverables to insurance companies and manufacturers that determine module acceptance and deficiency. The image below shows a solar module removed from a site after a recent inspection, with multiple cells damaged. Weinshenker suggested that the damage might have been caused by a solar panel above this one being dragged across the pallet, rather than being properly lifted.

The company also offers services for scanning solar modules as they are unloaded from shipping containers, emphasizing the importance of clear “module acceptance provisions” in purchase agreements with distributors and manufacturers. Spot-checking modules and informing manufacturers of such checks can help ensure the integrity of deliveries.

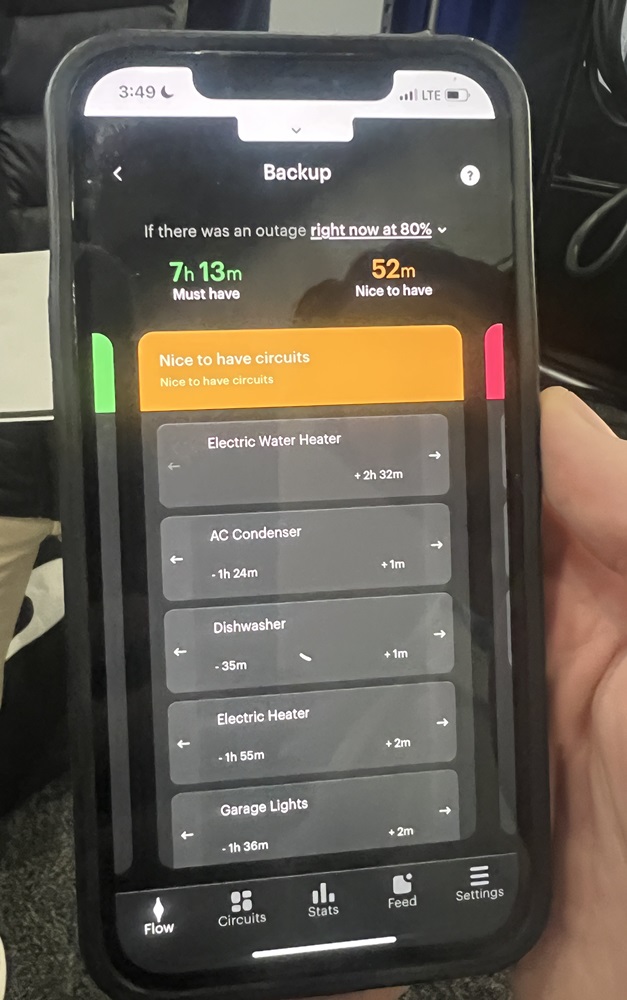

Span was onsite as well, showcasing its advanced electrical panel and new electric car charger at the booth. A representative demonstrated the company’s mobile app, which smoothly allows users to prioritize circuits powered by the battery backup and automatically recalculates the battery’s runtime based on the adjusted “must have” items.

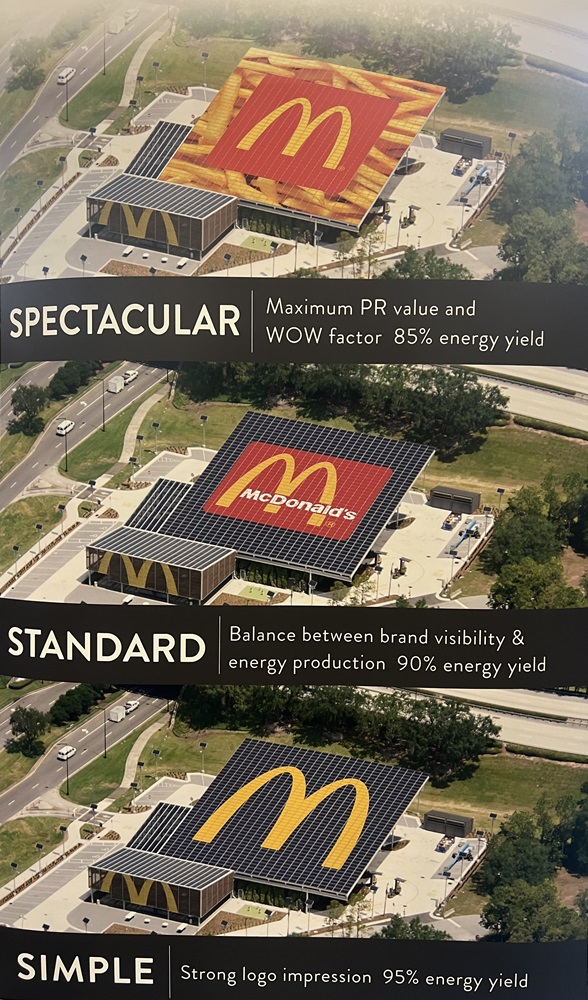

Sistine Solar refers to their printing technology as “SolarSkin,” which is a proprietary process that allows for the application of graphics on a thin-film polymer. This technology enables businesses and homeowners to customize the appearance of their solar panels to blend seamlessly with their roof or display any design they desire.

The company was open with pv magazine USA about their costs and pricing for printing in color on both residential and commercial sized solar modules. The printing costs are eligible for the 30% IRA tax credit. Sistine Solar noted that homeowner associations are a popular driver for residential solar consumers, while advertising is the top driver of commercial panel installations.

A graphic displayed at the booth illustrated the trade-off between “Maximum PR Value” and energy yield, with options for 85%, 90% and 95% module efficiency.

BrightView Vegetation Management offered a basketball shooting arcade game at the conference, with the highest scorer winning a pair of Apple Airpods. Based in Cambridge, Massachusetts, the company provides vegetation management services for ground-mounted solar facilities, as well as tree trimming services for commercial and residential solar projects.

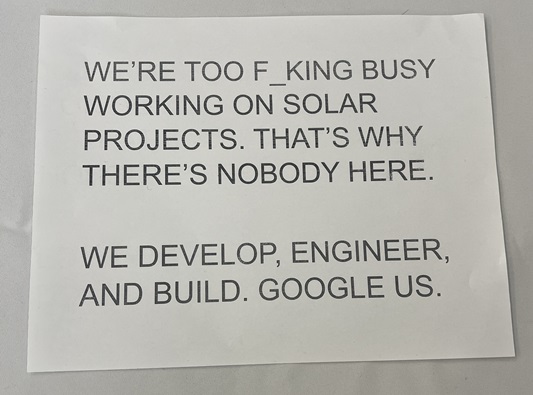

Invaleon, a residential, commercial, and utility solar engineering, procurement, and construction company from Haverhill, Massachusetts, also had a booth at the show. However, the representatives were a little too busy to attend on Tuesday.

Additionally, pv magazine USA had a booth at the event, with Matt Gallinger, Anne Fischer, Ryan Kennedy, Eckhart Gouras, and yours truly in attendance.

We look forward to seeing you on the floor at the next show!