Fourth Power, backed by Bill Gates’ venture firm, has developed high-density thermal energy storage based on thermophotovoltaic cells. The tech, which is reportedly 10 times cheaper than lithium-ion batteries, is based on the U.S. company’s patented liquid metal heat transfer system.

From pv magazine global

While thermal energy storage (TES) has struggled to take off to date, U.S.-based Fourth Power is taking a new technological approach to some of the cost and scale challenges. Its high-density TES system is based on its Guinness World Record achievement for high temperature in its patented liquid metal heat transfer system, which allows for operation at almost half the sun’s temperature.

“Until this innovation, I don’t think there has been an innovation in thermal fluid infrastructure in almost 100 years,” Fourth Power CTO Asegun Henry told pv magazine. “Utilizing PVC, steel, or nickel-alloy pipes has been around for a very long time, and that’s what everyone is doing.”

He said Fourth Power’s approach is based on knowledge of the struggles that other TES companies have faced in trying to scale the technology.

“The key is our liquid metal handling infrastructure, which allows us to transfer heat at fluxes more than an order of magnitude higher than traditional thermofluid systems,” Henry said. “This leads to higher power density and lower cost.”

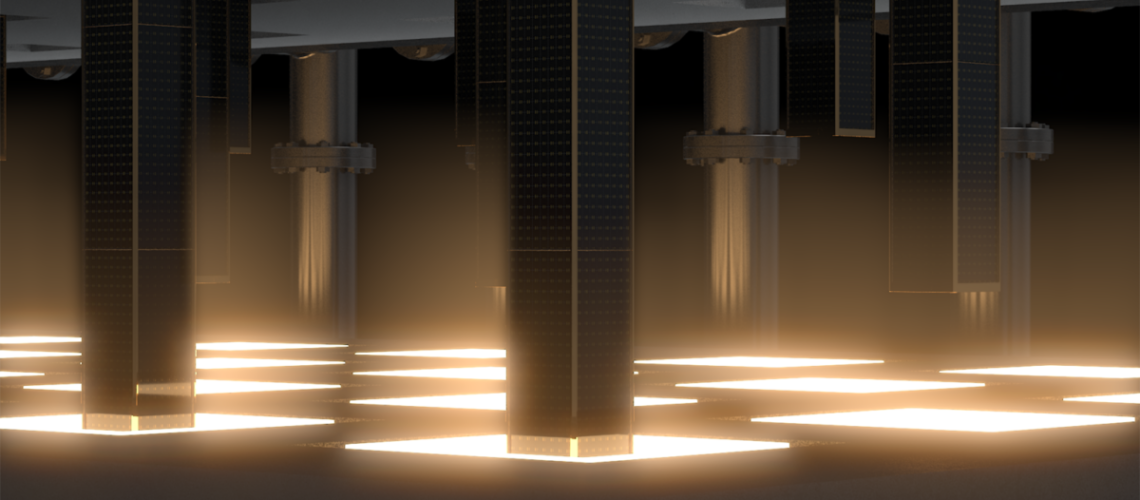

Fourth Power’s system converts renewable energy to heat, or thermal energy in a fully enclosed system roughly the size of half of a football field. The thermal battery heats liquid tin and moves it through a closed-loop piping system to heat stacks of carbon blocks until they glow white hot.

The system then exposes TPV cells to the light and converts it into electricity. This is similar to traditional solar generation but uses light from very hot — up to 2,400 C — graphite rather than light from the sun to produce electricity. The battery is sealed in a warehouse of argon gas to maximize system lifetime and ensure safety.

The system is modular and scalable by adding more carbon blocks to increase storage duration, allowing growth with the grid as renewable generation increases. Fourth Power says it can meet today’s short-duration (five-hour) needs and the future’s longer-duration (100-hour) needs. The company touts its flexibility to discharge within seconds as unique.

“We’re primarily focused on electricity and industrial heat,” Henry said. “To be more specific, we aspire for our technology to replace peaker plants in combination with renewable electricity generation.”

For power generation alone, Fourth Power’s roundtrip efficiency target is 50%.

“Our TPV cells have already set a world record at 41% – and we have designs to reach 50%,” Henry said. “For co-generation, the efficiency is near 100%.”

Finally, by using readily available and less expensive materials, the overall system cost is lower, enabling energy storage that is 10 times cheaper than lithium-ion batteries ($25/kWh-e vs. $330/kWh-e), according to the company.

On Tuesday, Fourth Power announced that it had received $19 million in Series A funding to scale its TES technology. The investment round was led by the venture capital firm DCVC, with participation from Bill Gates’ Breakthrough Energy Ventures and Black Venture Capital Consortium.

“After more than 10 years of research and development, we are grateful to reach this crucial milestone in our journey thanks to our funding partners who recognized the innovation and potential of Fourth Power’s thermal battery technology,” said Henry, who developed Fourth Power’s thermal battery technology when he was a professor at Georgia Tech.

The funds will also support the construction of a 1 MWh-e prototype facility outside of Boston, with a targeted completion date in 2026. In addition, it will facilitate rigorous durability tests and expand the company’s engineering team.

“Following the 1 MWH-e prototype facility’s successful completion, we plan to partner with utilities to conduct pilot projects designed for commercialization throughout 2026 and 2027,” Henry said. “We anticipate achieving our goal of installing full-scale, 100 MWh-e systems by 2028.”