There have been dozens of new solar panel factories announced since the passage of the Inflation Reduction Act (IRA). Some are even expecting to begin production within the next few months. This is not the case for 3SUN USA (and joint-venture partner Enel); the company hasn’t even broken ground on its chosen site in Inola, Oklahoma.

Credit: Enel/3Sun

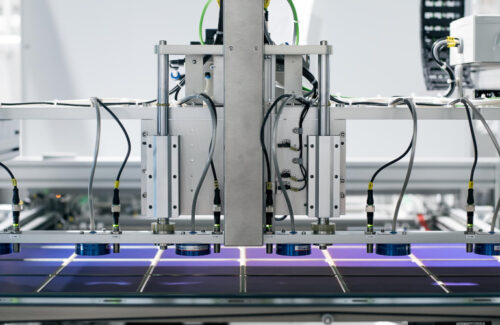

That’s not to say the company isn’t serious about the U.S. market. 3SUN is so serious about bringing its heterojunction technology (HJT) process to solar panels installed in America that it is building from scratch and making its own solar cells, which is more complicated than assembling solar panels alone.

“It’s a completely different game,” said Giovanni Bertolino, head of 3SUN USA, in an interview with Solar Power World about starting cell manufacturing vs. module assembly. “I’m reading about other players finding existing warehouses and converting them into module manufacturing plants. To make modules, you basically need a roof, electric power and not much more. CapEx investment is limited. Making the cell is completely different.”

3SUN must instead build a clean, controlled environment to manage the various gases and chemicals needed for cell production.

“This building is not just a simple warehouse,” Bertolini said. “You’re going to have a lot of piping in the ceiling, a lot of piping underground. The equipment to make cells is very sophisticated, very advanced, very expensive. And HJT is different from PERC and TOPCon. We have a higher level of sophistication in the tools to make those cells.”

HJT takes a traditional crystalline silicon solar wafer and adds a layer of amorphous silicon to increase light absorption for a more powerful hybrid cell. 3SUN has perfected this design at its factory in Italy that will reach 3 GW of annual manufacturing capacity by the end of the year. The Italian factory will essentially be copied over to Oklahoma.

3SUN is working through permitting with the state, and engineering designs for the factory are nearly finished. State and local incentives have been ironed out, and 3SUN has applied for a Dept. of Energy loan to help with the increased cost of making solar cells at the site. The company expects construction on the factory to start early next year, with panel production by the end of 2025. The site will first have a manufacturing capacity of 3 GW with the room to expand to 6 GW.

Making its own silicon cells in the United States will help 3SUN reach domestic-content bonus credits offered by the IRA, and the company is exploring other domestic supply chain options.

“We are collecting quotes and understanding the extra cost, if any, of having a bill of materials made in the U.S.,” Bertolini said. “There is some extra cost, but we believe that will be manageable.”

3SUN will make bifacial HJT cells and panels at the factory, mostly geared toward the utility-scale and large commercial markets. The company can take the same cells, cut them into thirds and assemble them into backsheeted-panels for the residential market, but manufacturing larger-format bifacial modules is the priority. Although U.S. product won’t begin rolling until 2025, 3SUN will have panels from its Italian factory available to U.S. customers next year.

Choosing a location

Site selection took time because 3SUN wanted to ensure the electricity used at the power-hungry factory would be as clean as possible. Oklahoma was eventually chosen because local utility Public Service Company of Oklahoma, a division of American Electric Power, can deliver 100% clean electricity, thanks to the region’s investment in wind power. 3SUN’s partner Enel has installed many wind farms and solar projects in the area, too.

Enel started in the 1960s as an Italian electric utility, and, through its division Enel Green Power, is involved with the development and operation of renewable energy plants worldwide. 3SUN’s factory in Italy initially began as a solar panel supplier for Enel projects in Europe. Enel will be a customer of 3SUN’s U.S. product, but there are plenty of other developer partnerships 3SUN will capitalize on.

3SUN had been looking at entering the U.S. market for a few years, but things obviously escalated after favorable credits were included in the IRA.

“We realized we had something very promising and strong in our hands with the technology we developed. After COVID and the disruption of supply chains and risk of being exposed to China in this industry, we decided to go ahead with the expanded plant in Italy,” Bertolini said. “The U.S. was in an even tighter position because of UFLPA, AD/CVD — getting panels to the U.S. was becoming more challenging. We thought our advanced technology, which competes very well with Chinese TOPCon, could deliver more value to customers. Then IRA passed. IRA was an accelerant, but the U.S. market was appealing even before.”

3SUN joins Heliene, Maxeon, Meyer Burger, Qcells and Silfab as companies with announced cell manufacturing plans in the United States. None are expected to begin production until late 2024 at the earliest.