The Singapore-based developer of glassless, frameless solar modules plans to invest nearly $35 million to renovate a facility in Indianapolis.

The newly launched Bila Solar announced plans to open a solar module manufacturing facility in Indianapolis, Indiana, where the company says it will produce 1 GW of glassless, frameless solar modules per year.

Bila plans to renovate an existing 150,000-square-foot facility and expects to employ 240 people once the plant is fully operational, stating that it will begin production in the summer of 2024.

“We’re bringing to the U.S. market ultralight modules that go where traditional solar panels can’t go,” said Mick McDaniel, VP and U.S general manager, Bila. “In Indianapolis, we found a central urban location, a diverse workforce and an entrepreneurial spirit – ideal for our out-of-the-box approach to making clean energy attainable for all.”

The technology behind the modules was developed in collaboration with the advanced materials industry. McDaniel told pv magazine USA that replacing glass with specially formulated composites was inspired by the windows in airplanes, which are not made from glass, and are lightweight, transparent, strong, flexible, durable and UV resistant. “These same characteristics are excellent for solar panels, so why haven’t we used them yet? The aerospace industry has figured out how and so our task was how to apply that to the PV industry in a cost effective way that met the needs of solar customers.” said McDaniel.

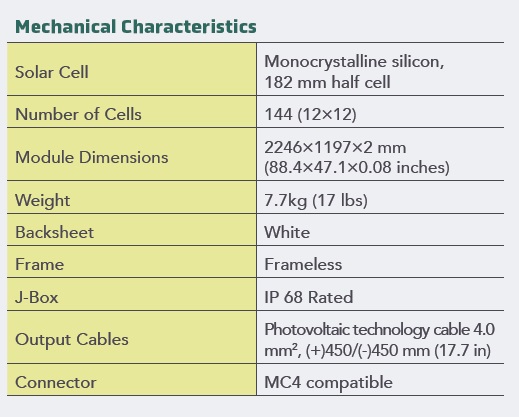

Bila plans to produce 520 W 144 half-cell monocrystalline modules, with an efficiency of 19.3%. The modules measure 88.4 inches by 47.1 inches by 0.08 inches. Made of an aerospace polymer composite, the module reportedly weighs 17 pounds, which Bila says is nearly 70% lighter than conventional glass-framed modules.

The light weight and thinness of the modules enable them to be deployed in various applications, including low load-bearing commercial and industrial roofs, waterproof membrane roofs, integration into vehicles for solar power, off-grid use and even on curved surfaces, the company reports.

McDaniel said the Bila Solar modules pass the same durability tests as conventional glass panels, including IEC 61215:2016, IEC61730:2016, UL61730 (USA), PID, and salt mist level 8 tests. He added that the modules have also undergone wind tunnel testing, damp heat, adhesion pull tests, flexibility stress tests and more. The modules come with a 12-year product warranty and a 25-year linear power warranty.

Bila is far from alone in setting up solar manufacturing facilities in the U.S. Earlier this month the Solar Energy Industries Association reported that an additional 85 GW of module manufacturing was coming to the U.S., following passage of the Inflation Reduction Act, which incentivizes onshoring manufacturing across the solar supply chain. Site Selection Group assisted Bila Solar with procuring state and local incentives for this exciting project.

“Indiana’s entrepreneurial ecosystem is strong, and we’re excited to welcome Bila Solar to our growing network of innovators advancing products that power the world,” said Governor Eric J. Holcomb. “With Bila’s new Indianapolis manufacturing operation, Indiana’s skilled workforce will be making solar energy more accessible and powering our growing clean energy sector to new heights.”

With its factory planned for Indianapolis, Bila has also designated the city as the location for its U.S. headquarters.