Georgia Gov. Brian Kemp today announced that EVA and backsheet maker Hanwha Advanced Materials Georgia intends to invest $147 million in a new manufacturing factory in Cartersville, Georgia. The facility will create more than 160 new jobs and supply materials to Qcells solar panels made within the state.

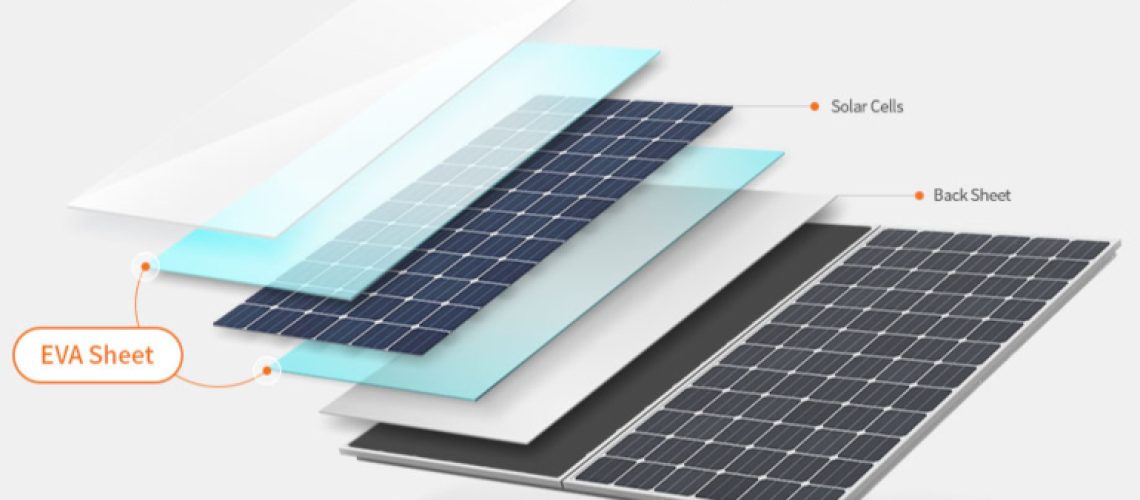

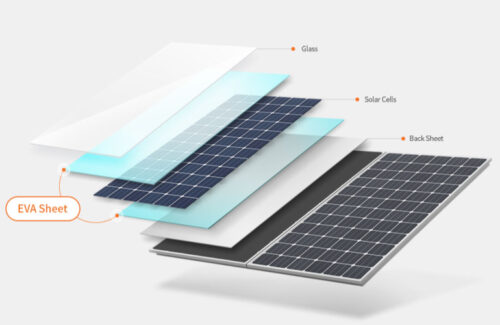

Hanwha Advanced Materials Georgia is a subsidiary of Hanwha Group and will supply Qcells with encapsulant film. Hanwha will be the only manufacturer in the United States with the capability of making EVA sheets. Endurans Solar in New Hampshire specializes in manufacturing solely backsheets.

Hanwha Advanced Materials Georgia is a subsidiary of Hanwha Group and will supply Qcells with encapsulant film. Hanwha will be the only manufacturer in the United States with the capability of making EVA sheets. Endurans Solar in New Hampshire specializes in manufacturing solely backsheets.

“The products we make are an important piece of the clean energy supply chain puzzle, and we are excited to meet this need,” said Inhwan Kim, CEO of Hanwha Advanced Materials. “Building our cutting-edge, advanced materials in Georgia will not only create new careers in solar but help bring more affordable, reliable clean energy to customers across the country.”

Hanwha will construct the new encapsulant facility in the same area as Qcells’ under-construction 3.3-GW multi-step solar factory. The encapsulant factory should come online by Summer 2024, while the Qcells factory is expected to begin production later in 2024.

“Qcells is doubling down on building a complete, domestic solar supply chain, and this recent investment is critical to making that happen,” said HG Park, President of Qcells North America. “Working with Hanwha Advanced Materials, our customers will soon be able to confidently know that the solar they buy from us was made right here in America.”

Today’s encapsulant announcement continues Hanwha Group’s move to become the dominant player in all aspects of the solar panel supply chain within the United States. Hanwha is the leading shareholder in REC Silicon, which announced that the entirety of its polysilicon supply coming out of Moses Lake, Washington, for the next 10 years will go to Qcells (approximately 3.6 GW annually). Qcells is also starting a 3.3-GW ingot, wafer, cell and panel manufacturing factory in Cartersville, Georgia, alongside its existing panel manufacturing sites in Dalton, Georgia. The company should have 8.4 GW of silicon solar panel capacity in the United States by the end of 2024.

Hanwha Group’s extensive investment in the solar panel supply chain is a result of the passage of manufacturing tax credits in the Inflation Reduction Act.

Qcells has also signed an agreement with a Canadian glass supplier to further its North American supply promise.